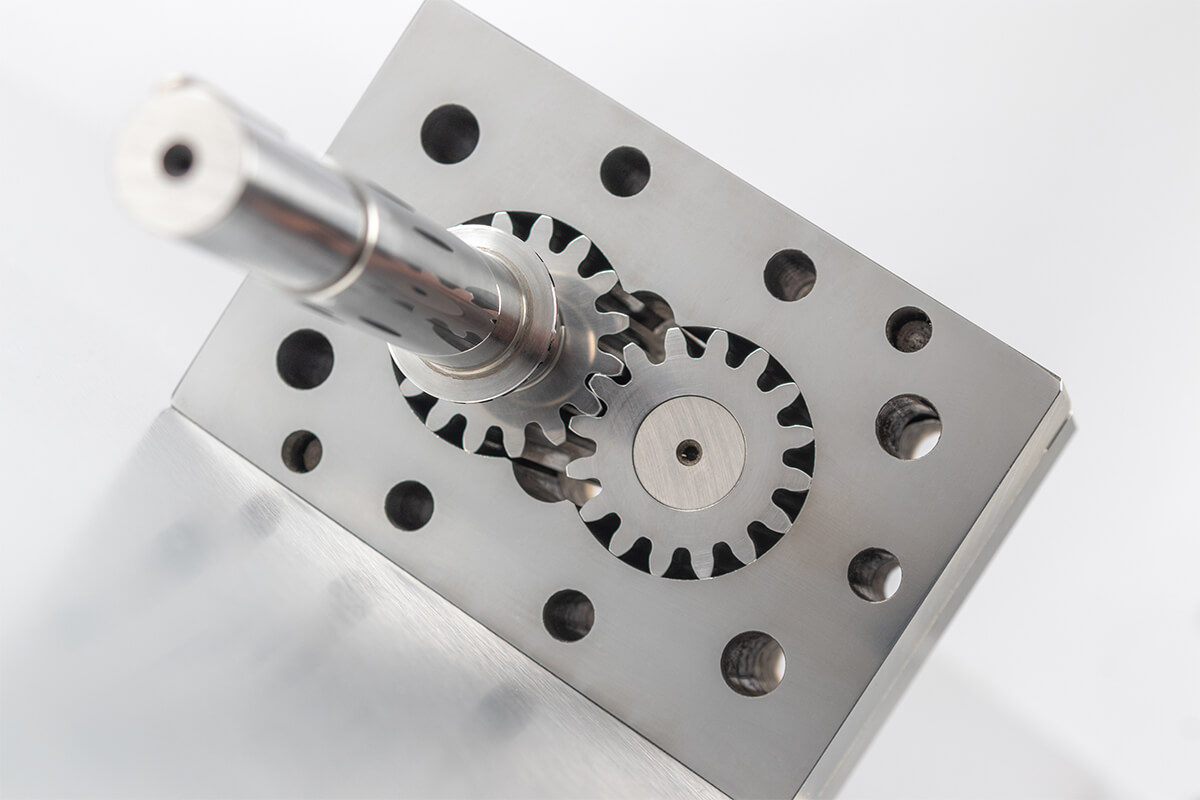

ZPDA external gear pump

ZPDA pumps are specifically designed for start-stop dosings. The low pulsation gear design provides constant flow with very rapid pressure build-up.

Internal clearances based on fluid viscosities are held within a few microns to insure the highest efficiency possible, even at high differential pressures up to 200 bar.

Depending on the application, DLC coatings are available for the wetted parts to provide additional corrosive resistance and abrasive particle resistance as well. Direct mounting of a VSE flow meter on the rear plate is also available for closed loop control.

Performance data

- Displacements 0.1 up to 26.0 cc/rev

- Speed 1 up to 200 rpm

- Viscosity 1 up to 1,000,000 mPas

- Temperature -20°C up to +150°C (standard version)

Special designs are available for deviating temperatures. - Operating pressure max. 200 bar (depending on rotation speed and viscosity)

Application areas

- Dosing of media without fillers: polyurethanes, isocyanate, polyol, catalyst, additives, silicones, fuels, adhesives, oils, hotmelt, paints

Advantages of the ZPDA external gear pump

- Specifically for applications with highest precision

- Low pulsation and precise dosing of the medium being transferred

- High precision start stop dosings

- Rapid pressure build-up

- Option for direct mounting of VSE flow meter

- Corrosion/wear resistant coatings

- To overview of further Beinlich dosing pumps